Batteries are already well known, and in recent years capacitors have become robust enough to start being used either alongside or instead of batteries.

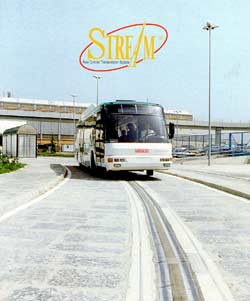

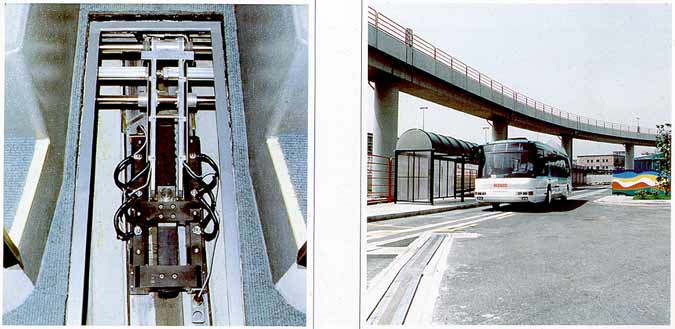

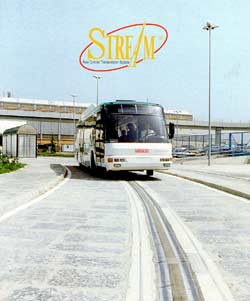

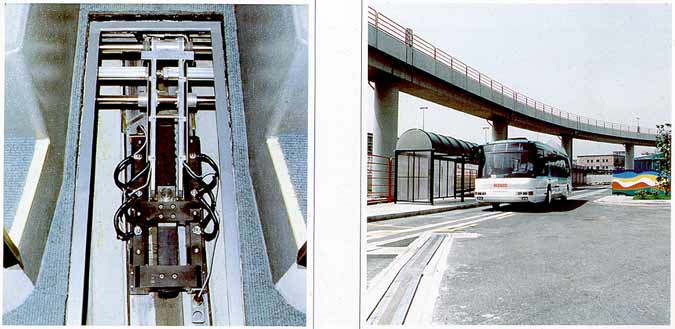

In addition, recent years have seen the emergence of some new ideas which now ready to be included in the range of clean air solutions of tomorrow. These include frequent fast charging of onboard energy storage and power collection from the road surface beneath the bus.

Most people know what batteries are about - after all, who has never used a torch / portable radio / music player / telephone / communications device (etc)? All of these use batteries and it would seem logical that if these

work well then buses should be able to be powered from batteries as well.

Real-world reality is such that so far battery technology has simply not provided the solution that people are hoping for. This is because (especially for large buses) batteries do not carry enough energy to power the bus for a full day.

If this were not so then both diesel and overhead wire trolleybuses would already have been replaced with battery buses.

Another issue with rechargeable batteries is that over time they degrade, which means that the amount of charge they can carry slowly reduces, and the reality is that (at present) none of the known battery

technologies has created a battery with the same longevity as the buses. Some battery technologies are still too new to be sure of exact facts but it is looking likely that all electric buses which use batteries to power the

vehicles will need their battery packs replacing at least once during their commercial lives. When the cost of the batteries is also bourne in mind this can be expensive! Often after a few years use batteries can be reconditioned,

but this process only adds working life to them, it does not return them to full 'as new' condition.

Money is not the only issue. Making / half-life reconditioning / disposing of spent batteries also has environmental consequences. Of course where there is the will to do things properly the environment is easily respected.

All the known and even some unusual battery technologies have been trialled with buses, including lead-acid, nickel cadmium (NiCd) and nickel metal hydride (NiMH). The present-day favourite is lithium-ion (Li-ion), one reason being

because these batteries are considerably lighter. Likely to replace Li-ion technology are batteries made from lithium iron phosphate (LiFePO4) / lithium ferrophosphate (LFP) as these avoid the use of heavy metals and poisonous

chemicals. Whilst they have a lower energy density than the more common Li-ion designs they are expected to offer longer lifetimes, better power density (the rate that energy can be drawn from them) and are inherently safer. This latter

point is important, it means that they are less likely to ignite if mishandled or experience a fault, this being such a significant safety challenge with other designs of lithium battery that complex electronics are required to try and

prevent it from happening. When lithium batteries ignite the resulting fires can be so hot (over 2,000° C) that they can melt concrete.

Note however that the operational, financial and environmental challenges related to battery buses are still easier to resolve than dealing with the human (ill)health consequences of fossil fuel exhaust fumes.

Battery Electric Buses Are Not A New Technology

In 1907 the horse bus reigned supreme. Although horse feed was expensive it was home produced§ and the waste material (horse dung) was a much sought-after saleable product (as fertiliser). Indeed, especially in the early years some

horse bus companies found that the funds raised by selling the dung made the difference between profit and loss.

§ it was estimated that as much as 25% of arable land within the British Isles was used to grow crops to feed the horses. |

|

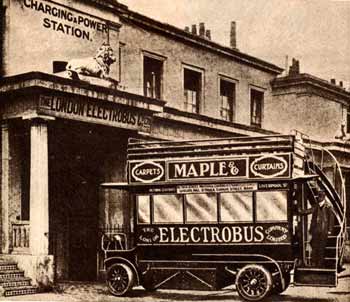

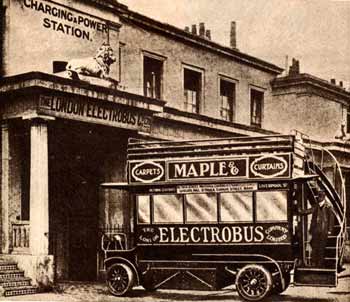

In July 1907 a small fleet of battery-electric buses entered passenger service in London. Operated by the London Electrobus Company they used lead-acid batteries which weighed 1.5 tonnes and when fully charged stored

enough energy for 40 miles (60km) of travel. To extend the distance the buses could travel in a day the batteries were replaced with a freshly charged battery pack at lunchtime. They were located in a cradle below the vehicle

(ie: underslung) and the process took just three minutes.

When introduced they compared very favourably with the small number (about 230) new-fangled petrol buses being trialled on London's roads, being of a similar size, cost and passenger capacity. However they were significantly more reliable and neither

made horrid noises which frightened horses nor gave off obnoxious waste gas fumes. |

|

Image: © New Society for the Diffusion of Knowledge (NSDK)

http://www.probertencyclopaedia.com/photolib/transport/Battery%20Bus%20

of%20the%20London%20Electrobus%20Company%201907.htm |

Additional Electrobus Information.

The first Electrobus service linked London's Victoria Station with Liverpool Street station. With the new service proving to be a success it was decided to expand operations to serve more destinations. This required funds to be raised on the stock market.

Initially there was no shortage of investors wanting to invest in the bus company, however that changed once it became known that the mastermind behind it was a fraudster who had a liking for fast cars and champagne. Because of this it proved impossible

to raise sufficient funds via the stock market.

What was not known at the time was that boss (Lehwess) was siphoning off as much as £1 in every £3 that the company raised. To help mask this he created a string of front companies which charged inflated prices to their customers (ie: other

companies within the group). For example, the Electric Vehicle Company (which built the buses) overcharged the London Electrobus Company (which operated the buses) by approximately £300 for each bus. Another scam was that The London Electrobus Company

paid more than £31,000 in advance for 50 buses whilst only 20 were ever delivered. In addition, Lehwess is also said to have used the bank account of the Electric Vehicle Company as his personal piggy-bank!

In 1909 the company went into liquidation. Some historians claim that the collapse was caused by technical drawbacks and a price war, these being comments which would make petrol buses look superior. In reality however it was the rate of financial attrition

which crippled the company. Lehwess even managed to scam the liquidators, convincing them that the eight buses he bought from them for £800 were only fit for spares and then selling them to a bus company in the Brighton, Sussex area for £3,500!

These buses then ran for another six years, which in an era when the life of motor buses was measured in months was quite an achievement and proved the reliability and ruggedness of the Electrobus buses.

By then however something else had happened which rendered these first generation battery buses technically obsolete and despite the hated noise & smells led to the widespread introduction of fossil fuel buses.

Links to more information:

http://www.economist.com/node/9465026

http://books.google.co.uk/books?id=a5CS6IcW0FEC&pg=PA38&lpg=PA38&dq=%22london+electrobus+company

%22&source=bl&ots=G80yxeApoR&sig=ROkkBAlITZD1kyvqcqBaEblNWVg&hl=en&ei=PCJITMqZNYyTjAfFwuzUDg

&sa=X&oi=book_result&ct=result&resnum=2&ved=0CBkQ6AEwATgK#v=onepage&q=%22london%20electrobus%20company%22&f=false

Why Motorbuses Triumphed Over Battery Buses.

Whilst the bankruptcy of the London Electrobus Company was a tragedy for the advancement of battery power during that era, what really changed everything was the 1910 advent of the B type motor bus.

Being mass produced it was cheaper than its competitors and - crucially - it was very reliable. Within just 18 months London's largest horse bus operator (the London General Omnibus Company - LGOC) had

completely replaced horse traction with these buses. By 1914 London's other bus companies had also stopped using horses.

Motor bus technology continued to advance rapidly and so did the carrying capacity of the buses within the legally mandated laden weight limits. Even if battery buses had of still been used the weight

of the batteries and the requirement for a stronger (thus heavier) vehicle to carry the batteries would have seen a greater proportion of the laden weight allowance having to be allocated to the unladen weight

of the bus than was required for the motorbus with its lighter engine. The resulting reduction in passenger capacity would have seen the battery buses being economically disadvantaged (fewer passengers = less

fares income). This is an issue which 100 years later still applies! (dateline April 2014).

However, the metric changed considerably in the 1930's after the electric buses had started being powered by overhead wires, with many designs of what became known as the trolleybus being physically larger than motor buses and hence being

able to carry more passengers (than motor buses) whilst remaining within the legally mandated overall weight limits.

|

Commercial Experience That Battery Technology

Is Not Yet Robust Enough For Large Buses

Some present-era examples of the issues regarding battery life can be found from Shanghai in China plus Rome and Pelermo in Italy.

Included in the public transports for the 2010 World Expo which was held in Shanghai was a dedicated fleet of 120 battery electric buses. During the Expo these were mostly used as tourist shuttles, for which their 80km (50miles)

range was sufficient. However they did not perform very well in the scorching summer heat of that year and in order to keep them available to transport Expo visitors the batteries had to be constantly replaced, cooled and recharged.

By 2013 the batteries had degraded to a point where they could only hold enough charge for 60-65 km (37-40 miles) of travel. As the linked news article below suggests, this restricts the services

on which these buses can be used, with frequent recharging between journeys becoming a burdensome necessity.

The bus operator reckons that after 4 - 5 years the batteries will need changing, and with the cost of new battery sets (per bus) being about 1.1 million yuan (US$176,765) so the financial burden represents a significant

deterrent for more widespread use of battery buses. See here:-

http://www.shanghaidaily.com/metro/City-routes-get-120-electric-Expo-buses/shdaily.shtml

Some reports suggest that rather than replace batteries some Chinese bus operators just scrap the vehicle. It is cheaper and easier.

Experience from Rome comes from a fleet of 30 electric buses which were introduced into service in 2005 and designed for a combination of both trolleybus mode and wire-free battery electric mode. The batteries were capable of powering the buses

for 10km of wire-free travel, although they only actually needed to travel for 3km in this mode plus spend 5-15 minutes laying over between journeys at the city centre bus terminus.

By October 2014 the batteries on all but four of these buses had become life-expired and needed replacing - at a cost of €30,000 each vehicle! Media reports suggest that the batteries

could not cope with the intensive demand placed upon them by the lengthy and busy unwired section in the city centre. As a result most of the fleet had to be taken out of service.

As Rome is extending its trolleybus network it was possible to use some of the new trolleybuses on this 2005 service. What is significant is that for use away from overhead wires the new trolleybuses

have diesel engines, so these have had to be used whilst travelling on the unwired section along inner-city streets and at the bus terminus.

Fortunately in 2016 the original 2005 vehicles were back in service, which implies that life-expired batteries had been replaced on these battery / trolley buses.

Palermo has 13 hybrid buses which date from 2001 and it is no longer able to use - because it cannot afford an estimated €400,000 for new batteries. |

Towing battery trailers behind the bus is an option which has the potential to solve the issues of batteries abstracting from overall passenger capacity and taking up valuable passenger inside the vehicle.

However trailers introduce many new complexities; in short this concept has not found favour - as otherwise many bus systems would be doing it!

Saskatchewan Transportation Company electric bus

and battery trailer at the Bus Service Center, Saskatoon. |

|

Image & license: SriMesh / Wikipedia encyclopædia. CC BY-SA 3.0

http://commons.wikimedia.org/wiki/File:BusAndTrailerSaskatoonSTC.jpg |

In the 1970's there were British trials with an electric Leyland National bus which towed lead acid batteries in a small trailer. The batteries weighed almost as much as the bus! The aim was to emulate the success of the milk float*

but experience showed that the 40 mile range of the batteries was significantly less than what had been hoped for. Had the experiment proven more successful then although there would have had to be much investment in battery handing and charging

facilities plus the creation of space for all the trailers at bus garages, with Leyland National buses being characterised by having noisy diesel engines which emitted waste gases that included plumes of black smoke so such investment would have

represented money extremely well spent.

*Milk floats were low-speed battery powered local area delivery vehicles used by milk delivery companies which each morning used to be familiar sights in British urban areas.

Emerging Technologies

Scientists are feverishly trying to find new solutions to battery life issues, it is not intended to report on them all but what may yet prove to be a gamechanger for passenger transport is that in June 2013 some German

researchers claimed to have created a lithium-ion battery that retains 85% of its ability even after 10,000 charges. In theory this means that if a battery is charged once daily then 10,000 charges will take over 27 years to achieve,

however since batteries are more likely to be charged several times a day so it could be that they will reach the 85% after just 10 years. This might still be viable, so that the batteries would only need changing once during the

expected lifetime of the bus... as ever we will only know through real-life experience when the right time has been reached. See here:-

http://www.treehugger.com/cars/german-researchers-create-lithium-ion-battery-retains-85-its-capacity-after-10000-charges.html

However lithium-ion batteries are extremely unstable and need very careful handling - as otherwise they pose a very severe fire risk. Apparently they contain a liquid electrolyte which is at the root of the problem, and scientists are

working on solid state lithium-ion batteries which are much safer - and it seems will also charge more quickly too. See here:-

http://arstechnica.com/science/2016/03/new-lithium-battery-ditches-solvents-reaches-supercapacitor-rates/

Then there is graphene, which when mixed with nanoparticles of silicon and metal oxides makes batteries of far greater capacity than those that exist today. For many applications graphene will be used in single-atom layers

which are known as two-dimensional crystals and the unanswered question which boffins are investigating is how many other materials, when used in this way, will have similar or even more useful attributes? Such

as powerful, safe, lightweight, fast-charging, long lasting batteries?

This is not the place to discuss why this is being suggested, but sometimes on alternative news discussion forums it has been suggested that magnetics can be used as part of a clean and safe source of energy. In tandem with

the sort of changes which are expected to be coming on stream when we start using magnetics will be wide ranging changes to our transport solutions, including the possible replacement of rubber tyres (tires as spelt

in the USA) with magnetic levitation. One reason why this would be so beneficial is that (as with diesel engines) the rubber tyres used on road vehicles represent another source of harmful particulate matter air pollution.

Battery Electric Bus Examples

Battery technology first became proven viable (if given financial support based on environmental issues) with smaller sized buses which are used on relatively short routes where the timetable has been arranged so that there is enough

time between journeys for the batteries to benefit from either 'top-up' charging or being replaced with a fresh set of fully charged batteries.

In the early 1990's Oxford, England, trialled a fleet of four electric minibuses. A report on their first 500 days of operation found that compared to similar diesel buses (and after

taking account of extra emissions at the power station) there was:-

21% less carbon dioxide, 21% less carbon dioxide,

98% less carbon monoxide, 98% less carbon monoxide,

42% less acid gases, 42% less acid gases,

93% less hydrocarbons, and 93% less hydrocarbons, and

95% less particulates (the fine particles of soot which clog our lungs, causing lung disease). 95% less particulates (the fine particles of soot which clog our lungs, causing lung disease).

Maintenance costs were comparable to diesels, but because of high design and development costs which were spread over just four vehicles they were twice as expensive to purchase. Their lead-acid batteries weighed-in

at 2 ¼ tonnes, making them about 2 tonnes heavier than the regular diesel buses.

Services using these buses in Oxford ended when local government funding was withdrawn. |

|

|

|

Oxford, England. A long wheelbase 'Optare MetroRider' electric minibus 'tops up' its batteries while awaiting its next scheduled journey.

This was done by means of a cable from a roadside

unit plugging in to a socket located on the bus.

A film showing these buses at this location outside the railway station which includes several scenes

(taken from different angles) of the bus driver physically plugging the power cable into the bus (and unpluging too) can be seen on YouTube at this link: A film showing these buses at this location outside the railway station which includes several scenes

(taken from different angles) of the bus driver physically plugging the power cable into the bus (and unpluging too) can be seen on YouTube at this link:  https://youtu.be/0ywz2_1-CYQ?t=3m40s.

https://youtu.be/0ywz2_1-CYQ?t=3m40s.

As the film also shows other buses this link is set to start at 3 minutes 40 seconds,

which is where the sequence with these buses begins. The focus on these buses then continues all the way to the end of the film.

Despite the environmental advantages, for many years the use of battery electric buses in British towns and cities was minimal. This is most likely because to Britain's cut-throat deregulated bus industry (where finance

is seen to be the only thing which matters) such innovation does not make (financial) sense. For the most part it has required central (or local) government finance for the private bus companies to invest in

electric buses.

Until February 2014 one of the few British conurbations which did use battery electric buses was St Helens, Lancashire. These were operated under the auspices of the Merseyside Passenger Transport Executive (Merseytravel)

who contracted out to private bus companies the operation of several free bus services which used very small battery electric micro-buses. |

|

|

|

One of the six St Helens Tecnobus Gulliver microbuses. Seen at Woodside Ferry Bus Station which connects with the Mersey Ferry.

Image & license: Colin Smith / The Geograph Project. CC BY-SA 2.0

http://www.geograph.org.uk/photo/128704. |

|

Also used in St Helens are six of these battery electric Tecnobus Pantheon minibuses. Note the twin axle rear wheels.

Image & license: Quackdave / Wikipedia encyclopædia. Public Domain.

http://commons.wikimedia.org/wiki/File:Tecnobus_Pantheon_1.jpg. |

Small fleets of similar battery electric buses are also used in several towns and cities around the globe, where they are often seen to provide a very effective transport solution in pedestrianised and so called

environmentally sensitive areas.

(Ahem, but surely our entire 'living space' aka: the whole planet should be regarded

as being 'environmentally sensitive' - not just a few high-profile streets in a city centre?) |

|

|

|

|

|

|

| Bordeaux, France, running on a city centre service through narrow streets which despite its small size it still only just manages to negotiate. |

|

Amalfi, Italy. These Tecnobus Gulliver buses can carry up to 20 passengers, 10 of which are seated.

Image & license: Jensens / Wikipedia encyclopædia. Public Domain.

http://commons.wikimedia.org/wiki/File:Amalfi_bus.jpg. |

|

|

|

Seen at the City Ferry terminal passengers board one of the 8 Tecnobus Gulliver electric microbuses which between 2008 and 2015 were operated by the Réseau de transport de la Capitale in the Old City district in Québec, Canada.

Image & license: zerojay (Jason Carter) / Flickr. CC BY 2.0

http://http://www.flickr.com/photos/zerojay/2727519625/. |

|

One of the Seoul Metropolitan Government (SMG) battery electric buses which are used on the Mt. Namsan circular routes, as detailed below.

Image & license: Wikipedia encyclopædia. CC BY-SA 3.0

http://commons.wikimedia.org/wiki/File:

Namsan_electric_bus_in_Seoul,_South_Korea.JPG |

In Seoul (Korea) the Metropolitan Government (SMG) in conjunction with Hyundai Heavy Industries and Hankuk Fiber have overseen the creation and introduction of some distinctively styled battery electric buses which are used on leisure-themed

services that serve Mount Namsan. Incredibly this service is promoted as being the first commercial all-electric bus service not just in Korea but anywhere on the planet!

These buses are 11.05 metres in length (about 12 yards / 36¼ ft), have a maximum speed of 100 km/hr (about 62 mph) and are said to be able to travel as far as 83km (about 52 miles) on a single charge.

Using high-speed battery chargers their high-capacity lithium-ion batteries can be fully charged in less than 30 minutes. The route terminus on the mountain has been equipped with four battery chargers. The press release references collecting "energy

generated from brakes when running downhill" which means that they also feature regenerative braking. Whilst this can be very beneficial when travelling downhill the inclines will drain the stored power even more quickly.

To reduce their weight and help maximise the distance they can travel between charges these buses make extensive use of carbon composite materials, instead of metal. They are also of a low floor design and are equipped with automatic

slant boards for wheelchair users. To enhance their visual appeal and create an aura of being different they are shaped like a peanut and decorated with attractive designs symbolizing the Namsan Tower and landscapes of Mt. Namsan.

The first five were introduced in December 2010 as part of a phased replacement of all 14 diesel buses on this service with the new electric buses. The phased introduction was to ensure that if there were any teething issues then it would be possible to

minimise the inconvenience which may be caused to passengers.

Additional information plus some photographs, one of which shows the physical cable 'plug-in' opportunity charging at the Mount Namsan route terminus:

http://kojects.com/2013/02/08/namsan-e-bus-first-commercial-electric-bus-worldwide/

Also from Asia, the Chinese BYD eBus battery buses which use Lithium Iron-Phosphate batteries have attracted attention of many transport operators planetwide. This is because BYD promote these buses as being able to travel 250km (155miles)

on one charge, in heavy city traffic, with the air-conditioning switched on. Trials in Poland in 2013 suggest that even further may be possible, albeit not the 350km (217miles) which the public transport operator in Warsaw, the Polish

capital city, has said that it needs from a battery bus to provide a full day's use from the one overnight charge. It is important to remember that these are new buses with new batteries - there is a need to see them in daily use for at least 5 years

to know the likely longevity of their battery packs. By the time we reach 2018 there will be no shortage of real-world data, as many thousands of these buses using these batteries are being introduced to various Chinese cities as well as 700 to the Dan

bus company in Israel and small experimental fleets to many bus operators in about a dozen nations around the planet. This includes London and Nottingham.

Batteries: How Often To Charge? Once A Day Or Frequently Daily?

There are several different ways of using battery buses emerging. The issue is that batteries offer a significantly lower energy density than a tank of liquid fuel, and whilst in theory it should be possible to compensate for this by carrying batteries,

these weigh so much and take up so much physical space that if the bus is to remain within legally mandated axle weight limits it risks ending up with a lower passenger capaciy. On the other hand, fewer batteries might mean that the bus can carry more people

but the distance it can travel before the batteries need recharging will be reduced.

The philosphy of Chinese bus builder BYD is that buses should only have their batteries charged overnight, when electricity is cheaper. They do not favour additional top-up charges during the day. To make this possible their buses carry a heavy load of batteries.

Especially for shorter distance city centre circular type services the total distance travelled during the day is so low that the BYD solution will work well.

Many other bus builders companies and some bus operators prefer to not devote so much space and weight to batteries and see a solution to top-up charging the bus batteries during the day, as then their buses will be able to carry more passengers - and possibly even

travel a longer distance during the working day. They also see how solar power can be harnassed to provide the power required for the frequent top-ups. beneft Fewer batteries also reduce headline bus purchase costs - and battery replacement costs.

Opportunity charging advocates also point to higher (greater) use of charging infrastructure during the day as helping justify the cost of installing it, whilst fewer batteries on the buses equate to 17% more passenger being carried,

High utilization of charging infrastructure and the limited battery weight in the opportunity charging concept makes it superior in cost efficiency towards overnight charging.

– The opportunity charging concept allows 17% more passengers.

– Overnight charged battery buses are convenient for testing the new technology in small scale, but have strong limitations in the daily range. This restricts it to slow routes, therefore with limited benefits.

-The opportunity charged buses can adapt to long workdays, high passenger capacity and high mileage. Thereby they deliver strong benefits for the city.

Batteries: How Often To Charge? Once A Day Or Frequently Daily?

Between December 2013 and August 2016 London trialed two of these 12 metre BYD K9 battery electric eBuses on the Red Arrow bus services (routes 507 and 521) which operate Monday - Fridays only. The evaluations suggested that these buses would be viable

on these services and placed an order for 51 eBuses from BYD, although only the chassis plus drivetrain and batteries, as it was decided to use British-built bodywork. The newer eBuses are seen further down this page.

Just before the first of the new eBus fleet started to arrive these two K9 buses were returned to BYD. It is understood that after refurbishment and upgrade to the latest specification BYD will use them as demonstrators. |

|

|

|

One of the two BYD K9 eBuses which London evaluated between 2013 and 2016. Their batteries are stored in a pod on the roof at the back of the bus plus inside the bus in two floor - to - ceiling compartments which are

located behind the driver on both sides of the bus. The 3,000kg weight of the batteries reduces the overall passenger capacity from 96 (on the diesel Citaro buses which are also used on the Red Arrow bus services) to just 69 passengers. This reduction

is to keep the vehicle's laden weight within the 18,000kg legal weight limit for twin axle buses.

The eBus seen in these images is working on route No.507, which is a short (2½ mile / 4km) city centre service where the end-to-end journey time is only about 15 minutes. Buses on this route tend to make one return journey

per hour, so even if used intensively they are unlikely to travel as much as 100 miles (160km) in the one day. This is significantly less than many buses travel on other services. These buses were also used on route 521, which although longer

is still a relatively short inner-city service.

As an aside, whilst in Poland a BYD eBus set a new global distance record for a battery buses using public roads by travelling 310km (192miles) from Warsaw to Krakow on one charge. What is more, its batteries only consumed

69% of their total available charge, so theoretically in optimal conditions the remaining 31% of charge could have seen it travel about 430km (265miles). However, this was achieved at night, when the roads were empty,

at an average speed of about 50km/h (30mph) and the batteries were still brand new.

A video showing London's BYD K9 eBuses in action has been placed on the 'youtube' film / video website and can be watched by clicking either the projector icon or the link below.

A video showing London's BYD K9 eBuses in action has been placed on the 'youtube' film / video website and can be watched by clicking either the projector icon or the link below.

http://www.youtube.com/watch?v=XEKJSMqhYKk

|

Also in London and originally operating on the two Red Arrow bus routes are two 12 metre Spanish Irizar i2e battery electric buses.

These buses use a combination of sodium-nickel batteries (for energy storage) and ultra-capacitors (for regenerative braking).

Capacitors are better than batteries (of any type) for this task as they can accept much higher rates of energy than batteries (ie: can absorb more energy more quickly). However they have much lower energy density (ie: can hold significantly less energy)

which explains why few buses use them as the primary mode of energy storage. |

|

Irizar i2e battery and ultra-capacitor electric

bus on route 507 at Victoria station. |

In 2016 these Irizar eBuses were transferred to bus route 108.

A video showing London's Irizar eBuses in action has been placed on the 'youtube' film / video website and can be watched by clicking either the projector icon or the link below.

A video showing London's Irizar eBuses in action has been placed on the 'youtube' film / video website and can be watched by clicking either the projector icon or the link below.

http://www.youtube.com/watch?v=xVlhroI6eg4

In May 2016 London started using the first of the planned five 10.2m K8SR double deck BYD battery electric buses on daytime bus route No.98 and night time route No.N98.

It is understood that to help them carry both batteries and a meaningful number of passengers these buses have been given a one tonne derogation on axle weight limits, nevertheless despite this

they still only carry 37 seated passengers upstairs and 17 seated passengers downstairs. |

.

|

|

|

One of London's 10.2m K8SR

double deck BYD battery electric buses. |

|

The crossed-out section at the back of the lower deck

shows an area that is unavailable to passengers,

presumably because it is where the batteries are stored. |

|

A video showing some of London's BYD K8SR double deck eBuses in action has been placed on the 'youtube' film / video website and can be watched by clicking either the projector icon or the link below.

A video showing some of London's BYD K8SR double deck eBuses in action has been placed on the 'youtube' film / video website and can be watched by clicking either the projector icon or the link below.

http://www.youtube.com/watch?v=VQM0O9Umu48

|

.

|

|

|

One of London's BYD D9UR chassis / ADL Enviro

200MMC EV body single deck battery electric buses. |

|

A montage showing (left) my smartphone's power lead

plugged-in to the USB power socket whilst taking this photograph

plus (right) a USB power socket with its blue LED light. |

|

In September 2016 the first of 51 BYD / ADL SEe type eBuses were introduced on London's two Red Arrow bus routes Nos. 507 and 521.

The 12 metre long buses comprise a BYD D9UR chassis with an Iron-Phosphate battery electric drivetrain and a British-built and Alexander Dennis Limited (ADL) Enviro 200MMC EV body.

They feature 21 seats and are permitted to carry a maximum of 72 standing passengers. The seats at at the back of the bus are reached via steps. The priority seats have folding armrests.

The seat backs include USB power sockets, this being the first time that such has been available on Londons' buses. Note however that the sockets are quite small and easily overlooked!

This is London's largest ever fleet of single deck pure electric buses, and the first fleet of battery electric buses to operate in central London since the London Electrobus Company introduced a small fleet of them in 1909.

A video showing London's BYD / ADL SEe type eBuses in action has been placed on the 'youtube' film / video website and can be watched by clicking either the projector icon or the link below.

A video showing London's BYD / ADL SEe type eBuses in action has been placed on the 'youtube' film / video website and can be watched by clicking either the projector icon or the link below.

http://www.youtube.com/watch?v=uy0EbBKbf7g

|

The second British city to use these buses will be Liverpool, which will be receiving 12 in 2017.

These will operate on city centre circular routes Nos. 26 and 27 which are also known as The Belt.

On this fleet there will be 38 seats plus space for 36 standing passengers. |

|

|

Charging The Batteries

Most battery electric buses use 'conductive charging', which is also known as 'direct wired contact' or 'direct coupling'. This well tried and proven system has traditionally involved plugging a cable into a socket on the vehicle.

However other variants exist which involve stationary buses making physical contact with various types of overhead power sources (not trolleybuses / something else) and road surface power supply conductors.

A variant of conductive charging sometimes sees the batteries being removed from the vehicle for recharging. If several sets of batteries are available then immediately replacing them with a fully charged set of batteries

would mean that the bus could be back in service within minutes / without having to wait for the removed batteries to be recharged.

In addition to 'conductive charging' another way to charge the batteries (whilst they still remain in the bus) is via electromagnetic 'inductive charging'. This is further explored under the Roadway Power heading below. |

|

|

|

A battery electric Wrightbus Streetair midi bus demonstrating plug-in charging at a bus and coach industry exhibition in November 2016.

The image on the right is a montage showing the charging post and (above it) the plug-in connection.

Opportunity Charging

The term opportunity charging refers to daytime 'topping up' the stored energy in the batteries whenever and wherever there is a chance to do so - such as whilst calling at a bus stop - rather solely charging the batteries overnight (in a

bus garage) or swapping out batteries with a freshly charged set during the day. Frequent charging in this way means that the bus can use fewer batteries, as there is no need to even try to make a single charge last for a full day's use.

Fewer batteries equates to a smaller space requirement and less weight, both of which can result in a higher overall passenger capacity.

Both conductive and inductive methods are suitable for opportunity charging, however the bigger question relates to the batteries which (depending in the type of battery) might be damaged - such as experience a

shorter overall life - if charged too quickly.

Note that opportunity charging is only possible at locations where the required physical infrastructure has been installed in advance. What is possible however is that as the technologies described below mature some cities will

install charging facilities at some bus stops on the basis that they are used on an 'as required' basis. As batteries start to degrade this scenario will assist in keeping buses in service and delay the inevitable time when fresh batteries will be required.

The disadvantage of opportunity charging is that it requires a bus to be stationary. This can delay the service, although if carried out at busy bus stops where the dwell time is often longer than usual so quick top-ups of 30 - 120 seconds

duration (or at bus termini during the layover between journeys) the recharging period will probably not even be noticed.

With battery buses which also operate for some of the time as trolleybuses it is possible to recharge the batteries at all times the bus is connected to the overhead wires, whether stationary, in motion, carrying passengers...

This is known variously as SlideIn charging and In Motion Charging.

This solution is being adopted in several cities, including Beijing, China; Rome, Italy; São Paulo, Brazil; Landskrona, Sweden; Esslingen, Germany; Budapest, Hungary; and more.

In Beijing trials since 2008 which used battery buses with the aim of replacing the trolleybuses found that not only was it often difficult to find unobstructed locations for opportunity charging but that the commercially viable life of the

batteries was just too short. In addition there was disquiet over the high cost of installing all the charging equipment. With severe urban air pollution making conversion to diesel buses politically unacceptable so Beijing is now expanding its trolleybus fleet

with vehicles that have lithium-ion batteries (for use on short unwired sections) which are re-charged whilst travelling in trolleybus mode.

In Landskrona the single trolleybus route is being used as a means to electrify other bus services without installing any extra infrastructure. The experimental bus simply switches between the various routes, operating in either battery or grid-connected trolleybus modes

as appropriate. At a later date the bus is to be modified to be compatible with a tram power supplies too. A further phase is also planned but at present the technology does not currently exist - see roadway power below.

Additional information:

http://ec.europa.eu/environment/life/project/Projects/index.cfm?fuseaction=search.dspPage&n_proj_id=3922#RM

http://www.slidein.se/en/about-the-project/background/

Another advantage of recharging whilst travelling under trolleybus overhead wiring is that this is compatible with busy roads served by multiple bus routes. Whilst opportunity charging works well on single bus routes which do not share termini, life

could become somewhat chaotic if the bus stops are on the public highway, and more expensive (because many charging stations will be required) when serving multiple high-frequency bus routes (eg: buses on each route come every 5-8 minutes). The scenario being envisaged here

is one where three (or more) buses all arrive at the same time and all need to recharge their onboard energy storage...

|

Viennese Electrics

A battery electric midi bus can be found in the Austrian capital of Vienna where in September 2012 the first of 12 Italian EL Alé Rampini battery electric buses which have a

capacity of 30 passengers started being used on two inner city routes. These 7.72m (a little over 25ft) midi buses are powered by lithium iron phosphate batteries which provide a total capacity of 96kW

and provide enough energy for about 120km - 150km (74 - 93 miles) of travel. In addition to powering the vehicle's Siemens three phase synchronous motor, the batteries supply the onboard electronics, including winter

heating and summer air conditioning. At each terminus they receive a top-up rapid charge lasting about 15 minutes. In addition they are given a full slow charge overnight. The transport operator has said that these buses consume

1.3 - 1.6 kWh/km which rises to 2.5 kWh/km during the coldest winter months. The electric heating explains the higher winter energy consumption.

As the images below suggest, daytime charging is achieved by the bus raising its roof-mounted tram-style pantograph to reach a dedicated pair of trolleybus-style twin overhead wires. Because both live and return feeds are required

so the pantograph is split electrically into two sections.

Vienna has a large well established tram system and at some charging points its 600v dc power supply system is used to recharge the batteries. Since many of Vienna's trams use regenerative braking so often it is these buses (and not the trams)

that end up benefiting. The buses also regenerate their own braking energy. |

.

|

|

|

Rear view of two route 3A EL Alé Rampini battery electric buses on line 3A during their dwell time at the Schottenring Underground bus stop.

Image & license: darkweasel94 / Wikipedia encyclopædia.

Public domain with correct attribution.

http://commons.wikimedia.org/wiki/File:3A_Zelinkagasse.jpg |

|

EL Alé Rampini battery electric bus at charging station náměstí Bořislavka whilst on demonstration in Prague, Czech Republic.

This image clearly shows the twin-wire trolleybus style of overhead wiring from

which the pantograph collects electrical energy.

Image & license: ŠJů / Wikipedia encyclopædia. CC-BY-SA-3.0

http://commons.wikimedia.org/wiki/File:

Bo%C5%99islavka,_Siemens-Rampini_(03).jpg |

Important Safety Consideration - Whilst Recharging Via Direct Contact

The system used in Vienna of frequent daytime (fast) top-up charging of batteries is becoming seen as one of the ways that larger buses can overcome the inability of batteries to provide enough power for a full day's use.

It is important that any vehicle which is physically connected to an external source of electricity has robust isolation of its electrics from the body of the bus. Trolleybuses are double isolated and as part of the daily checks that are carried

out before they enter public service (eg: braking system is OK, legally mandated external lights work, tyres are OK, etc) they also have an earth leakage test to ensure that their electrics are safe. Perhaps all buses which

recharge onboard energy storage systems using physical connections to external sources of power whilst in the street domain should also undergo similar daily checks. It would be a terrible incident should the bodywork of a bus that is being

recharged become live and either someone touching the bus or boarding / alighting it ends up being used by the electricity as a pathway to earth. |

One advantage of the system used in Vienna is that if the wires are long enough and power supply system robust enough it could be used by several buses simultaneously. But locating pantographs on bus roofs adds weight, equipment

costs and complexity. In addition, there are extra staff training and maintenance costs.

A different solution which moves all the equipment off the bus uses an inverted pantograph which is lowered to power conductors located on the vehicle's roof. Although only being able to serve one bus at a time this is likely to

become the industry standard.

This is looked at in greater detail at the end of the section about fast charge batteries. |

|

Model vehicles demonstrating two 'above bus'

opportunity charging solutions which use split pantographs,

as seen on a stand at the Milan UITP exhibition in June 2015

left: comes down from above on to the bus roof

right: rises up from bus roof to overhead conductors

- as used by the EL Alé Rampini battery electric buses. |

Fast Charge Batteries

One of the problems with batteries is that they risk being damaged if charged too quickly. Fast charging will also shorten their service life. By way of contrast, bus passengers do not want to be waiting even 10 minutes just so the bus can recharge

its batteries! In an attempt to resolve this an American company has developed a type of battery which it claims is more suited to being fast charged.

Known as Altairnano (nLTO) these batteries use nano lithium titanate, with the titanium being what makes it more able to accept rapid charging and discharging. However, nLTO batteries have a lower inherent voltage than other types of

lithium-ion battery, which leads to a lower energy density and the implication of this is that they are less powerful. As yet it is too soon to be sure of their viable service life,

some estimates suggest six years, others think that it may be much longer. Or shorter. The reason for the uncertainty is that whilst conventional lithium-ion batteries can typically be charged about 1,000 times before they are considered

no longer useful, laboratory tests suggest that nLTO batteries should be able to achieve over 16,000 charge and discharge cycles at rates up to 40 times greater than common batteries, and still retain up to 80% of their initial charge capacity.

This helps explain why trials with real buses are needed to discover real-world results.

By 2013 there were several experiments underway using nLTO battery powered fast charge buses. Included in these trials are some specialist overhead power supply charging systems, albeit with different implementation styles.

In America the first bus which used these batteries was the Proterra EcoRide BE35. This is a 35ft (10.7 metre) 35 seat lightweight carbon fibre / glass fibre composite vehicle. These midi-buses continue to be introduced in an ever

growing number of locations, albeit (so far) only in small numbers. They are fast recharged by stopping with the back of a bus below an overhead power supply unit so that a recharging arm can be lowered to make contact with conductors on the roof of the bus.

Also in the USA, the EBus Trolley is available in a 100% electric version which originally used these fast charge batteries. So far one transport company uses five of these 7 metre, 22 seat replica vintage trolley style buses. This is LINK Transit of rural Wenatchee,

Washington State. Charging is also through the use of an arm which is raised from the back of the bus, and whilst therefore the theme is similar the physical equipment is different to that which the Proterra bus uses.

In 2014 one LINK Transit trolley was switched from nano lithium titanate to lithium-titanate iron-phosphate batteries which have been found to need less frequent charging and provide a longer range. |

This incompatibility between different charging infrastructures may matter, or may not. Certainly for proof of concept trials this is not an issue, however it will aid wider adoption of opportunity charging if all buses

used the same design of open source / vender-neutral charging infrastructure.

More information and photographs can be found at these links:

http://www.scientificamerican.com/article.cfm?id=battery-powered-electric-bus

http://www.masstransitmag.com/press_release/

12029899/link-transit-launched-five-battery-electric-trolleys

https://www.youtube.com/watch?v=E3IHqJK7_YY

(a short film showing the charging process).

http://www.flickr.com/photos/38680645@N03/7193294832 |

San Joaquin Regional Transit District (RTD) has two of these all-electric Proterra BE35 buses seen here below the "Fast Charging" station.

Image & license: SanJoaquinRTD / Wikipedia encyclopædia.

CC BY-SA 3.0

http://commons.wikimedia.org/wiki/File:

Proterra_Electric_Bus_at_Charging_Station.jpg |

|

In Sweden fast charging trials began with diesel hybrid buses in Umeå (which is in northern Sweden). Although the buses are called Plug-In Hybrids and often include electric plug motifs on their sides they are actually recharged by

raising two small roof-mounted pantographs to reach an overhead power conductor which looks somewhat like a metal bar a couple of metres in length that has been divided into two electrically isolated sections (+ at the front, - at the back). This

is known as a Bůsbaar (the word Busbaar has a small ring ° - as used in some languages - above the letter u) and was created by a Spanish company named Opbrid, in conjunction with some well-known railway industry

component supply companies.

Once the bus has stopped below the Opbrid Bůsbaar the bus driver only has to press a button to initiate the fully automated charging process, during which time s/he can remain in the bus (this is probably very much appreciated in inclement

weather!) The pantographs automatically raise for 5-10 minutes whilst the batteries receive a partial recharge. Full recharges take place overnight.

Trials in Umeå commenced in 2011. An Opbrid Bůsbaar charging station is located at one end of the route and it serves two Hybricon Arctic Whisper fast-charge hybrid buses. These are modified Volvo 7700 series type hybrid buses which are

capable of running with the diesel engine switched off. They have 100 kWh Valence batteries which hold enough charge for up to three hours of fully electric operation, and the aim is that by constantly 'topping-up' the charge the buses will run

in electric mode at all times, albeit with the reassurance that if there are any delays in reaching the Bůsbaar (eg: traffic congestion) then the bus will still have the diesel engine as a fall-back. With near arctic conditions in the winter

and 30° heat in the summer, these trials in Umeå also test the ability of the batteries to withstand a very wide range of climatic conditions. The trials are a collaboration between Hybricon (Sweden), Opbrid (Spain), e-Traction

(Holland), Umeå Energi and Umeå city council. As an aside, electricity in Umeå is sourced renewably.

In April 2014 it was announced that to meet the desire of the bus company to reduce charging times trials are underway with ultrafast charging at 625 amps (400V DC) with the goal being to charge at 500-1000 kW as this would enable charge times of

just 2-3 minutes. Trials in 2014 included two 650 kW charging stations and for 2015 it was planned to build a 950 kW charging station. These buses use batteries specifically designed for high charging rates and cold temperatures. In addition,

the buses with the 100 kWh batteries have been replaced with buses that use different battery types and pack sizes for different charging solutions (as well as a diesel range extender). For 672v charging the buses use 40 kWh battery packs.

Information as per the article, which includes a mix of amp, volt and kWh data. |

More information and photographs can be found at these links:

http://opbrid.info/umea-reference-site

http://www.greencarcongress.com/2010/10/opbrid-20101006.html

http://www.hybricon.se (Swedish language only)

http://www.opbrid.com/

http://www.prweb.com/releases/2010/10/prweb4603564.htm

http://www.prweb.com/releases/2011/04/prweb5221714.htm

http://www.mobility-magazine.com/fast-charging-electric-with-arctic-whisper/593

http://opbrid.info/umea-reference-site (some excellent photographs)

http://chargedevs.com/newswire/hybricons-arctic-whisper

-electric-bus-demonstrates-ultrafast-charging/ |

Promotional photograph as supplied with the press release

about the Gothenburg Hyper Bus project.

Note the two small pantographs which rise

up to engage the elevated power supply rail. http://www.prweb.com/releases/2012/7/prweb9656753.htm |

|

The next location to trial these technologies was Gothenburg, where three Volvo 7900H parallel-type hybrid buses were modified to be able to access an external power source. An Opbrid Bůsbaar was located at each end of the route and the plan was

for the buses to travel as much as possible in battery electric mode. As the buses have 28kWh batteries but only use approximately 8kWh per journey it would have been expected that they would have been able to stay in pure electric mode at all

times, however the route has some steep hills and with the vehicles being the "electric assist" parallel type of hybrid bus where both electric and diesel motors / engines are connected directly to the drivetrain so there are times when the diesel engine

turns on to help the electric motor get the buses up the hills. The buses can also use their diesel engines if they are delayed in traffic and miss some opportunity charging sessions.

The trials in Gothenburg were known as Hyper Bus Project, with the word Hyper being an acronym coming from Hybrid and Plug-in Extended Range Bus system. This project started in September 2011 and ended in 2014. The actual bus service trials

commenced in June 2013. In November 2013 it was announced that the buses in the trial used 81% less diesel fuel per 100km travelled than regular diesel buses.whilst overall energy consumption - including both diesel and electricity - was down by 61% compared to a Euro 5 diesel bus.

More information:

(Hyper Bus Project website) (Hyper Bus Project website)

http://www.hyperbus.se/engelskwebbplats/hyperbus/abouthyperbus.4.7f30c2451341eef1dc180002873.html

(May 2013: Initial results of trials with plug-in hybrid buses) (May 2013: Initial results of trials with plug-in hybrid buses)

http://news.volvogroup.com/2013/02/25/plug-in-hybrid-bus-saves-75-per-cent/

(November 2013: Field tests prove without doubt the benefits of plug-in hybrid buses) (November 2013: Field tests prove without doubt the benefits of plug-in hybrid buses)

http://news.volvogroup.com/2013/11/13/plug-in-hybrid-buses-reduce-fuel-consumption-by-81/

(Also see the Opbrid comment with additional information further down this web page) (Also see the Opbrid comment with additional information further down this web page)

http://www.greencarcongress.com/2013/11/20131114-volvo.html

(Opbrid webpage about 2013 Gothenburg project with Volvo plug-in hybrid buses) (Opbrid webpage about 2013 Gothenburg project with Volvo plug-in hybrid buses)

http://www.opbrid.com/index.php?option=com_content&view=category&layout=blog&id=36&Itemid=59&lang=en

This link leads to a page from this website which explains the differences between the various types of hybrid propulsion systems:

http://citytransport.info/Hybrid.htm |

.

Volvo bus photograph as used on both the ABB

press release about The Vender-Neutral Fast-Charge

Standard and The Hyper Bus Project website.

Click this link to see a closer view of the twin

pantographs (in lowered position) on the bus roof  |

|

Opbrid promotional photograph showing one

of Gothenburg's Hyper Bus Project buses

at a 300kW Bůsbaar charging station.

pic.twitter.com/zEq07xEJkx |

A Vender-Neutral International Fast-Charge Standard Emerges

In 2014 ABB and Volvo formed a global partnership to create and commercialise a standard charging system for electric and hybrid buses using both an automatic roof-top connection system at bus

stops and overnight cabled charging systems at bus garages.

It seemed sensible that where possible existing open standards-based direct current (DC) protocols would be used, but since none existed for opportunity charging at bus stops the partnership formulated

a standardised automatic e-bus fast charging solution, including the wi-fi communications protocol between the infrastructure charging solution and the bus, the electrical

interface and specifications for the rooftop automatic connection system (ACS).

ABB were already experts in fast charging systems, having delivered such for automotive, utility, government and retail customers including nationwide networks in Denmark, Estonia and Holland.

The idea behind this partnership was that by there being a single international standard to which all urban bus industry and charging infrastructure supply manufacturers could adhere it would facilitate a more rapid expansion of electric

bus networks in our towns and cities whilst avoiding the nuisance of rival and incompatible proprietary systems - such as occurred in the 1980's in the video tape industry.

Some readers may recall there being several incompatible rival videotape systems. VHS and Betamax were the main variants, but there were others as well.

Some readers may recall there being several incompatible rival videotape systems. VHS and Betamax were the main variants, but there were others as well.

Then there were issues because of different standards for colour television - PAL, NTSC, SECAM - which varied according to nation or region. Unless you owned a rare multi format video player, videotapes recorded in one format would not work on machines designed for a different format, even if the same physical system.

A right mess! For those who have no idea, this link may be of interest:

http://en.wikipedia.org/wiki/Videotape_format_war

|

The newly designed ACS uses four conductors - two for power, one for a signal to ensure that all is well and the fourth as an earth - for the bus bodywork. This may sound like belt and braces safety

but it significantly reduces the chance of a freak event resulting in danger. For instance, a very windy day when something is blown on the roof of the bus during the charging process which touches both the bus

body and live conductor at the same time.

What may also be of interest here is that an electric short-circuit protection system was also devised in the 1980's when kerb guided trolleybuses started travelling on kerb guided rights of way which were shared with trams.

The concern was that if the tramway overhead wire should break and fall on to the bus it could make the bus bodywork live, and if this happened at a joint bus / tram station and if someone on the station platform or a boarding / alighting

passenger touched the bus and station platform at the same time then they would be used as part of the electric circuit to earth. To avoid this (and the consequent danger of electric shock, or worse) the buses were fitted with a special

earthing shoe which would automatically lower on to a tram rail as part of the station stop, as this ensured that the body of the bus would be electrically grounded. Trams do not need these special shoes because their steel wheels automatically

create the ground connection, whereas buses use rubber-tyres which electrically insulate them from the ground.

More information:

http://www.abb.com/cawp/seitp202/6ce621212d3e502ac1257d1c002eb875.aspx

http://articles.sae.org/13457/ (Also includes some data about TOSA [as seen below] charging rates for other buses

and photographs of the Opbrid Bůsbaar.)

http://chargedevs.com/newswire/abb-and-volvo-form-partnership-for-bus-fast-charging/

http://www.prweb.com/releases/2015/05/prweb12729101.htm

(Opbrid announce their support for the new open standards opportunity charging system; this press release dates from after it had been created).

Because of its involvement in this project in September 2014 Luxembourg became the first city to receive some opportunity charged Volvo 7900 Hybrid Concept buses. Eventually it will have 12 such buses, delivery is being phased over time with six scheduled to arrive in 2016.

They are destined to be used on various routes around the city.

More information:

http://www.wort.lu/en/luxembourg/abb-and-volvo-buses-12-fast-recharging-hybrid-buses-planned-for-luxembourg-53cd28bab9b3988708048882

http://www.sales-lentz.lu/en/information/news/world-premier-volvo-7900-electric-hybrid |

|

In December 2014 Hamburg started using three Volvo Electric Hybrid opportunity charge buses on a new bus service that has been named Innovation Route 109. Over the coming years this 10km route will host buses with many so called innovative

propulsion systems, including fuel cell, pure battery, rigid buses, articulated buses, and (for reference) plain diesel buses. The idea is to create a working laboratory where all the different propulsion systems benefit from identical conditions of use so as to discover

their strengths and weaknesses. This bus route is 9.3km in length, has 23 bus stops and in the rush hours an end - to - end journey can take up to 37 minutes. There are two charging points at each terminus.

More information and photographs can be found at these links:

http://www.greencarcongress.com/2014/12/20141219-volvo.html

http://chargedevs.com/newswire/volvo-electric-hybrid-bus

-begins-operation-on-hamburgs-innovation-route/

|

Volvo 7900 Electric Hybrid bus on Innovation Route 109

opportunity charges its batteries.

Image & license: spoorjan / Wikipedia encyclopædia. CC BY-SA 3.0

http://commons.wikimedia.org/wiki/File:HVV_1493-III.JPG |

In January 2015 Volvo and Siemens signed an agreement to market the concept further, including installing it in Hamburg, Stockholm and Gothenburg.

More information:

http://www.siemens.com/press/en/pressrelease/?press=/en/pressrelease/2015/mobility/pr2015010104moen.htm&content[]=MO

http://www.volvogroup.com/group/global/en-gb/_layouts/CWP.Internet.VolvoCom/NewsItem.aspx?News.ItemId=149238&News.Language=en-gb

In March 2015 trials extended to Stockholm, the Swedish capital city, using eight Volvo 7900 Electric Hybrid buses which have been given human names! This is as part of the ZeEUS project (Zero Emission Urban Bus System) which commenced

in February 2014 and includes the expertise of more than 40 participating companies and organisations, covering innovative electric and extended range hybrid bus solutions in eight cities: Barcelona, Bonn, Glasgow, London, Münster, Plzeň,

Cagliari and Stockholm. The ZeEUS project ends in 2016 by when it is expected that sufficient experience will have been gained for some of the services to continue operating, albeit on a commercial basis.

In Stockholm the opportunity charge buses operate on route No. 73, which passes through the heart of the city centre. There is a charging station at each end of the route, using overhead equipment which was supplied by Siemens. After a quick charge of about

six minutes the fully charged batteries will power the buses in pure electric mode for about 7km after which the bus relies on its biodiesel fossil fuel engine. The demonstration part of the project is scheduled to continue

to the end of 2016, after which the plan is to continue the project on a commercial basis.

More information:

http://corporate.vattenfall.com/press-and-media/press-releases/2014/electric-hybrid-buses-with-quick-charge-facility-demonstrated-in-stockholm/

http://dailyfusion.net/2014/06/hybrid-electric-buses-stockholm-29748/

http://zeeus.eu/ (ZeEUS project) |

.

|

|

|

One of the pure electric Volvo 7900H Electric Concept buses built for Gothenburg and Siemens ACS at the Milan 2015 UITP exhibition.

As is seen in the image on the right, the H-shaped pantograph head is at right-angles

to the copper contacts which are on the bus roof.

The next stage in Gothenburg occurred in June 2015 when fully electric route 55 was introduced. This is served by 7 Volvo 7900 Electric Hybrid buses and 3 Volvo 7900 pure Electric buses, all of which opportunity charge at both termini. These buses offer passengers free wi-fi internet

and mobile telephone charging facilities. A new innovation is that one of the termini bus stops in indoors - this is only possible because the buses use electric power. The electricity used to charge these buses is sustainably sourced.

More information:

http://www.goteborgelectricity.se/en/node/19504

http://www.siemens.com/press/en/pressrelease/?press=/en/

pressrelease/2015/mobility/pr2015060258moen.htm&content[]=ICMOL&content[]=MOTPE&content[]=MO

(Siemens press release which includes a photograph inside the bus station showing a bus during the charging process)

http://www.multivu.com/players/English/7544351-volvo-electric-bus-route-launched/

http://busandcoach.com/news/articles/open-standard-charging-stations-for-gothenburg/

http://busandcoach.com/news/articles/indoor-buses-volvo-electricity-shows-the-possibilities/

(A much more indepth article which also talks about the Volvo ElectriCity project in general, the bus stop inside a library(!) and how electric buses could redefine bus travel)

http://www.volvobuses.com/en-gb/news/2016/oct/volvo-abb-inaugurate-charging-station.html

http://www.greencarcongress.com/2016/11/20161109-heliox.html

Commercial Exploitation Starting 2016

Starting in 2016 Volvo pure electric and hybrid buses suitable for opportunity charging via the overhead charging stations became commercially available as part of the Volvo product range.

Volvo market the overhead charging system as OPPCharge

In October 2016 an OPPCharge charging station built by ABB was brought into use outside Volvo’s electric bus terminal in Gothenburg. ABB call their charging stations as Heavy Vehicle Charger (HVC). The text below comes from the press release about this new facility.

It is installed outside Volvo’s electric bus terminal in Arendal, Gothenburg and is a joint reference project between ABB and Volvo Buses. The aim of this cooperative venture is to cooperate on the development and commercialisation of electric buses and electric hybrid buses

equipped with systems for DC opportunity charging using open standards. Demonstrations of buses and charging stations both as products and systems offer a clear picture of what installation at the customer’s premises looks like.

With the new charging station, Volvo is demonstrating that the company’s electric buses are compatible with chargers from several different manufacturers. The buses operating on route 55 are now charged using systems delivered by ABB and Siemens.

It is also noteworthy that Siemens have also demonstrated that their charger is compatible with electric buses built by both Volvo and Solaris.

Another charging station supplier is Heliox. In 2016 one of the public transport operators in Luxembourg (Sales-Lentz,) ordered three Heliox Fast Charge Systems with OppCharge open interface for route terminus opportunity charging in Luxembourg. These will be used with their four Volvo 7900 electric buses.

These charges are expected to start being used in "second quarter 2017".

OPPCharge In The UK

One of the first cities to start using OPPCharge was expected to be Edinburgh, Scotland, where Lothian Buses route No.30 is planned planned to use 24 Volvo 7900 electric buses and two charging stations on. However this has been delayed.

Another new technology which Edinburgh's buses were going to include is geo-fencing. This is an automated AI (artificial intelligence) system which detects and uses the location of the vehicle to change how it operates. The functions it can automatically control include switching the bus into an enforced pure electric mode (to eliminate tailpipe pollution

when passing through air quality management areas) and the ability to restrict the speed at which the bus can travel. This latter feature is promoted as being for use when passing schools, although the information does not state whether at all times (even nights? weekends? other times when the schools are closed?) or only when it is actually beneficial, this being in the

mornings / afternoons when the children are actually travelling to and from school.

In October 2016 it was announced that two other British cities would be using OPPCharge technology ahead of Edinburgh. These are Harrogate and London.

London will be first, using two Wrightbus SRM double deck hybrid buses that will have sufficient battery capacity for up to 7km in pure electric mode before switching to diesel hybrid mode. The SRM buses are a new design which marries a bus body that is based upon the Wrightbus New Bus For London and New Routemaster buses with

a variant of the well established Volvo B5LH double-deck chassis.

(More information about these buses can be found on the A Bus For London page).

As yet the choice of bus route remains unknown, as does when the trials will actually commence. Included in the challenges are the siting of the roadside charging units, especially if they need to be in the street as then they will need planning permission from the relevant local government - this being a process which is rarely quick.

Harrogate will have eight pure electric 7900e buses and three charging stations which will be located in Harrogate bus station. These buses will work on three short Transdev Blazefield bus routes. The system is expected to commence in 2018.

In 2016 the Canadian city of Montreal also started a three year experimental public service using the open-standard OPPCharge system. However the buses to be used will come from the Volvo's North American subsidiary, Nova Bus.

Montreal will use two opportunity charging pylons which will be located at both terminus bus stop on route No.36 - Monk. These will top-up charge the batteries with enough power for 15 km - 25 km of travel. There will also be full slow charges overnight. The trials will include three Nova LFSe electric buses.

This is part of trials by the urban transport operator (Société de transport de Montréal - STM) designed to choose an electric bus technology for its entire network, so that it can switch to only having electrically powered buses.

Additional reading:

http://lothianbuses.com/news/article/Lothian-Buses-to-order-next-generation-green-buses

http://busandcoach.com/news/articles/2016/electric-volvo-fleet-for-transdev-blazefield-in-harrogate/

http://busandcoach.com/news/articles/2016/world-premiere-for-volvo-b5lhc-electric-hybrid-double-deck/

http://www.stm.info/en/about/major_projects/electrification-surface-system

|

.

|

|

|

Wrightbus bodied with Volvo B5LHC chassis two door SRM double deck hybrid bus under an

OPPCharge overhead pantograph equipped power suuply unit at a bus industry exhibition in November 2016. |

.

|

|

|

The OPPCharge logo as seen on the

lower nearside corner of the windscreen. |

|

Inside the bus, showing the battery pack just in front of

the centre doors, with a (very high!) luggage area above. |

PIC LOOKING UP TO CHARGER SHOWING H SHAPED CONDUCTORS

Other Fast Charging Projects

There are several other fast charging systems which basically have the same aims but involve other bus manufacturers, bus operators, governmental bodies, etc., Those which are known about are detailed below.

EDDA Bus project

This German system is part of the Fast Charging Systems for Electric Buses in Public Transport joint research project funded by the German Federal Ministry of Education and Research (BMBF). It includes the Fraunhofer Institute for Transportation and Infrastructure Systems IVI

plus several bus / electrical industry companies. Trials with the opportunity charged Solaris Urbino 12 EDDA bus by the Dresdner Verkehrsbetriebe (DVB) began in November 2014 and in June 2015 it entered public service on the 5.2km circular route No. 79 Mickten - Übigau.

Journeys normally take 16 minutes, and since the route operates every 20 minutes this leaves just four-minutes at the terminus for battery charging. This is said to be sufficient for the high-power charger to recharge the batteries and pre-heat the passenger compartment, if

required. The batteries receive a full charge overnight.

Power for charging the bus is taken from the tramway overhead wiring. The charging infrastructure includes a transformer that stabilises output voltage at approximately 748v. The transformer is needed because although the tramway is energised at a nominal 600v this fluctuates

widely - between 500v and 1000v! - with acceleration and regenerative braking of the trams being the cause.

This bus route only needs one bus and when this electric bus is undergoing maintenance it is replaced with a diesel bus.

More information plus some images:

http://www.fraunhofer.de/en/press/research-news/2015/June/fast-charging-electric-bus-does-overtime.html

http://www.edda-bus.de/en.html

http://www.gizmag.com/fast-charging-edda-electric-bus/37860/

http://www.greencarcongress.com/2015/06/20150601-edda.html (This page has what is probably the best image showing the charging station).

TOSA

TOSA was launched in May 2013 at the UITP exhibition in the Swiss city of Geneva. During the exhibition and for one year afterwards the single Hess Swisstrolley4 articulated electric bus (which has what is described as a small car-sized battery pack) was

used on a short demonstration service which served just a few bus stops between Geneva Airport and Palexpo exhibition centre.

The TOSA system features two different types of charging stations which are located at bus stops along the vehicle's route and at termini. The 400kW en route charging facilities are designed to provide a partial top-up in just 15 seconds,

whilst passengers alight and board. The 200kW termini type charging facilities are deliver a 3 - 4 minute full recharge. To avoid sudden large drains on the urban electricity supply system the fast charging stations use capacitors rated at 3kWh

to store electrical energy that has been slowly drawn from the 50kVA urban power grid. In addition the buses receive a 30 minute 50kVA charge at the bus garage. The onboard energy storage needs recharging every 1km - 1½ km, which works out at about

every second or third bus stop.

The power is transmitted to the bus via a laser-controlled moving arm located on the roof of the bus which connects to an overhead rail that is approximately 1m in length. This current collector is moveable in several directions,

so that the vehicle benefits from a little leeway in its stopping position beneath the power rail. The system is designed for speed, so even as the bus is arriving at the stop the fixed overhead receptacle is being detected

and the rooftop contact arm begins to align itself laterally to it. Once achieved the charging arm rises up from the bus and makes contact. After a safety check has ensured that a proper connection has been made with the stationary bus voltage is applied.

The flash-charging technology and the onboard traction equipment used in this project were developed by ABB and is optimised for high-frequency bus routes in key urban areas, carrying large numbers of passengers at peak times.

The project is a collaboration between TPG; (Transports Publics Genevois - the Genevan public transport operator); OPI - as coordinator for industrial projects; SIG (Geneva power plants) for the power supply; and ABB.

More information:

http://www.tosa2013.com/

http://www.gizmag.com/tosa-bus-model/32564/

http://www.trolleymotion.ch/index.php?L=3&id=115&n_ID=1796

Note that Geneva already uses both (overhead wire electric) trolleybuses and trams, and concurrent with this trial is introducing a fleet of new trolleybuses which would be expected to still be in use in the 2030's and,

given that trolleybuses often last 30+ years, the 2040's. The tramway has also only just received some new vehicles, one of which is involved in regenerative braking trials using capacitors.

TOSA is not seen as a replacement for trolleybuses, not least because the cost of installing a TOSA system (including the buses, charging stations and electrical supply infrastructure) is expected to be comparable to a new trolleybus

system. Its primary aim is to create a different way to convert diesel / other fossil fuel bus services to electric traction. The systems' reliance on batteries still represents a future liability.

By spring 2014 it was thought that experience of the TOSA system was such that work should start on the next stage, this being the conversion of a 9km diesel bus route which does not serve the city centre (No.23)

to TOSA buses. These plans were confirmed in July 2016.

Although this 9km bus service uses 11 vehicles for the new electric service the route is to modified slightly and there will be 12 electric articulated buses, which will use 13 en-route flash-charging stations plus three terminus four depot feeding

stations. The flash stations will provide 15 second 600-kilowatt boost charges, whilst buses will also receive longer (four / five minute) full recharges at the route termini.

This project is being enacted as part of a strategy for the cleanest possible urban air, which is recognised as only being possible through the elimination of all diesel buses from the built-up area.

Ah, if only similar thinking applied here in Britain too! |

Tosa promotional image of the trial bus at a bus stop charging point. |

|